The baked brick making village in Mang Thit district was formed more than 100 years ago, known as the most famous and largest red brick and ceramic production place in the Mekong Delta.

The golden age of brick villages stretches 30 km in Vinh Long city, Long Ho and Mang Thit districts with more than 3,000 kilns in operation. Currently, there are about 800 brick kilns, stretching over an area of 3,000 hectares, of which the most concentrated are along the Tay Cai canal to the section bordering the Co Chien River - a tributary of the Mekong River.

The brick kilns located along the river are convenient for production and transportation of goods to other places. During its heyday in the 1980s, it created jobs for thousands of people. In addition to supplying bricks and ceramic products for domestic needs, they are also exported to foreign countries.

Each house usually has 2-5 brick kilns. After 2000, the brick firing profession in Mang Thit gradually declined due to high production costs and changing user habits. Many houses demolished brick kilns to do other things. Some kilns are retained but do not work, over time the plants and grass are full, covered with moss.

The furnace is built from thousands of evenly carved bricks, arranged in a circular tower architecture. On average, 10 workers will complete a furnace in half a month, using more than 30,000 card bricks. Each oven can hold about 15,000 tablets, fired for 20 days to produce the finished product. Workers use rice husk ash to burn bricks to help save costs and raw materials.

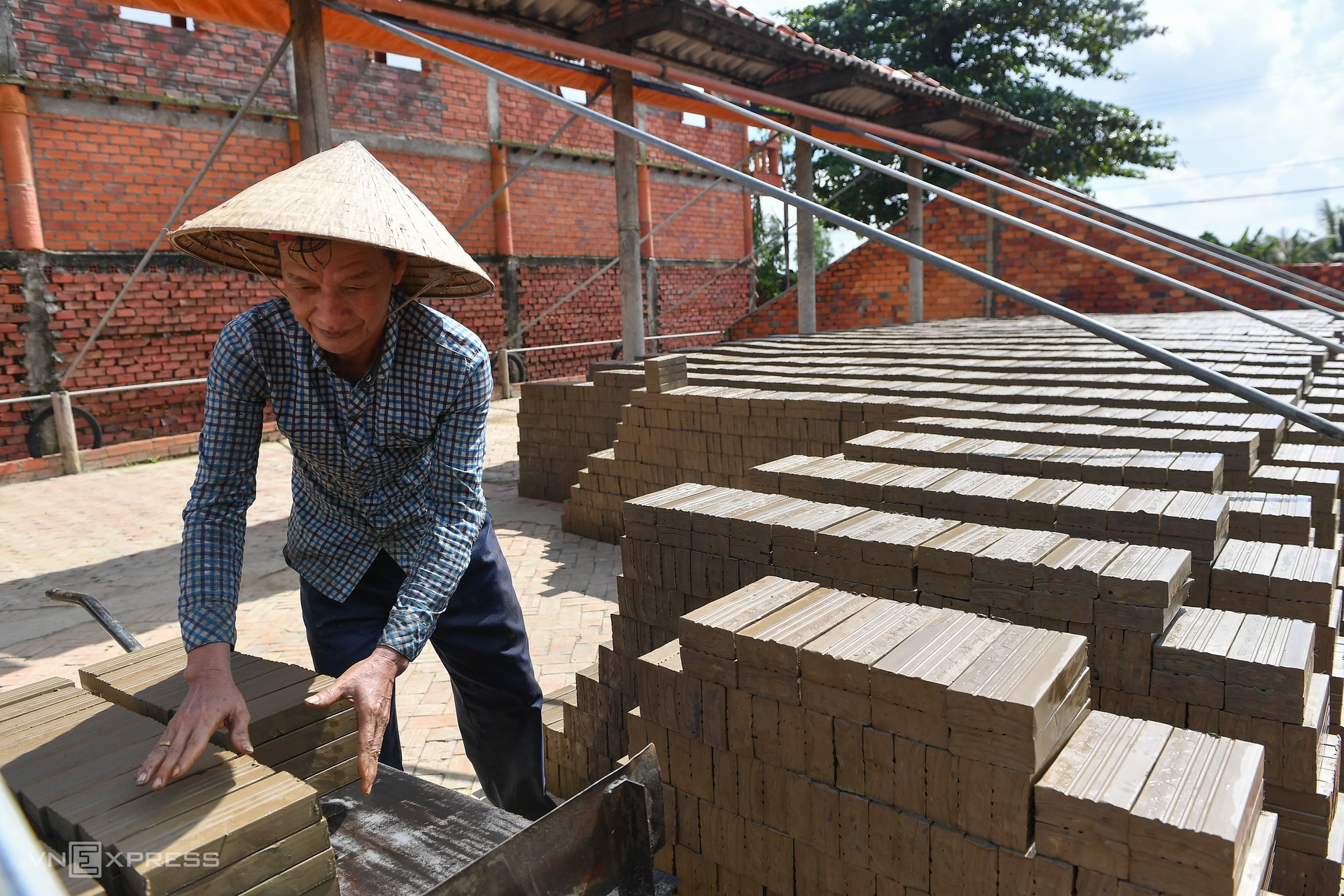

A brick kiln is usually 7 m - 12 m high, shaped like a round tower, gradually smaller at the top. After firing, the bricks will continue to be completed in the finished stages to be consumed. Clay is taken from canals and canals in Vinh Long and Tra Vinh and brought to the oven, then it will be chopped into pieces. Today's brick factories only maintain a few workers.

Some pottery kilns in Mang Thit, Vinh Long, in addition to serving production, are also open to tourists. The designs and products of the pottery village are also richer. In addition to traditional bricks and pots, ceramic pots of various shapes, decorative ceramics were also born, meeting market demand and serving visitors to buy as souvenirs.

Every day, hundreds of tourists come to the brick and pottery kilns to visit. Visitors come here to learn and experience how to make pottery and the culture of traditional craft villages, take pictures with ceramic decoration spaces.

From My Thuan Bridge to Dinh Khao ferry, visitors go about 10 km to the area along the Co Chien River, where many brick kilns are concentrated. The place where many guests check in is an area with many old, old brick kilns, brick drying yards with many characteristic cylindrical towers.

According to VNE